Screw-in hooks and hangers play a pivotal role in the installation and maintenance of vehicle headliners, offering practical solutions for securing fabric and other interior components. Whether restoring a classic car or upgrading a modern automobile, these small but essential hardware pieces ensure that headliners remain taut, secure, and free of sagging. This article explores the function and advantages of screw-in hooks and hangers specifically designed for headliner applications in vehicles.

Understanding Screw-in Hooks for Headliner Installation

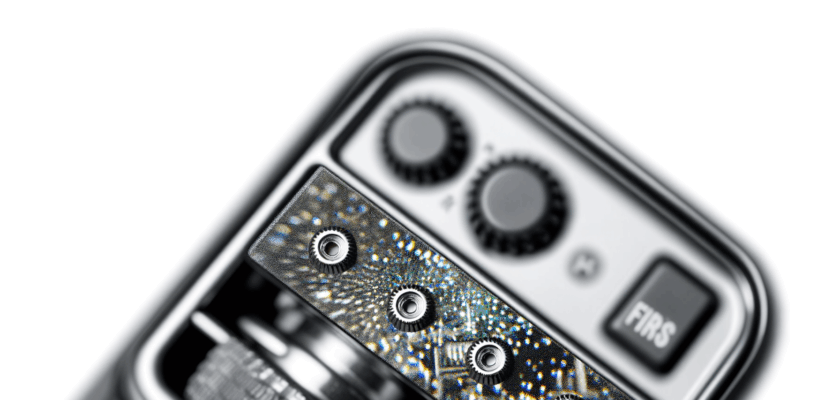

Screw-in hooks are specialized fasteners designed to be embedded into the vehicle’s roof frame or support structure, providing anchor points for attaching the headliner fabric or foam backing. Unlike adhesive-based methods, screw-in hooks rely on mechanical fastening, which offers increased durability and reliability over time. This installation technique is particularly favored in automotive upholstery due to its ability to maintain tension evenly across the headliner surface.

Typically made from corrosion-resistant metals or coated alloys, these hooks are engineered to withstand the variable temperature and humidity conditions inside a vehicle. Their design often includes a curved or looped end, allowing fabric or wire to be threaded securely without slipping. The ease of installation is a notable feature: installers can quickly screw these hooks into pre-drilled holes, making them a preferred choice for both professional mechanics and DIY enthusiasts.

In addition to their functional benefits, screw-in hooks can also accommodate different sizes and thicknesses of headliner materials. This versatility allows them to be used across various vehicle models and interior designs, from compact cars to larger SUVs. As a result, their role extends beyond mere fastening devices to critical components in maintaining the aesthetic and structural integrity of automotive interiors.

Benefits of Using Screw-in Hangers in Vehicles

One of the primary benefits of using screw-in hangers is the secure and long-lasting hold they provide for headliner materials. Unlike adhesive strips or clips that may degrade or loosen over time, screw-in hangers create a robust physical connection that resists vibration and movement. This durability reduces the likelihood of sagging or drooping headliners, which are common issues that can detract from a vehicle’s appearance and comfort.

Another advantage is the relative ease of maintenance and replacement. Because screw-in hooks are mechanically attached, they can be unscrewed and repositioned without damaging the fabric or underlying structure. This feature enables easier repairs and modifications, making it cost-effective for vehicle owners and workshops to refresh or update the interior without extensive disassembly.

Finally, screw-in hangers contribute to a cleaner and more organized installation process. They minimize the need for adhesives or complex fastening systems, which can introduce mess or require curing times. By simplifying the installation, these hooks help reduce labor time and improve the overall quality of the headliner fit. This efficiency is particularly valuable in manufacturing and restoration settings where precision and consistency are critical.

Screw-in hooks and hangers for headliners represent a practical and effective solution for automotive interior fastening needs. Their mechanical reliability, ease of use, and adaptability make them indispensable in both professional and DIY vehicle restoration projects. As car owners and mechanics seek durable, neat, and maintainable options for headliner installation, screw-in hooks remain a trusted choice ensuring interiors look polished and perform well over time.